Share on facebook

Share on email

If you want to know more about wire shelves, click and ask! Click and fill in the form

We’ve all heard of TV shows like “How it’s made?”. These formats are quite popular among audiences and not without a reason. At least once most of us have probably found themselves in a situation where we saw an appliance or an object at a store and asked ourselves: how does the manufacturer do it? I would say it lies in the human nature, being very curious about the world and everything in it. That is why we want to show you how shelve manufacturers actually do it. More specifically, we will go step by step through the stages of manufacturing wire shelves.

Wire shelves, regardless of their size, shape and the material they are made of (stainless steel or other), are manufactured in the same way. The only difference is in the material they are made of and the subsequent treatment, e.g. plastification. As a matter of fact, we, as a manufacturer, make wire shelves from the beginning to the end. That is why we can afford to offer such a variety of products at attractive prices using stainless steel and other appropriate materials to make the wire. This enables us to create countless wire shelf designs, differing in material (not only steel wire shelving), dimensions, color, bar distance and shape. This allows us to customize your wire rack or shelving for storing different products. This way, you can choose a design to match your expectations.

There is a number of factors that are decisive for your wire shelving, regardless of whether you need shelving for applications in the food industry, hotel industry or other areas where wire shelving is common.

Every manufacturing process begins with people. It is people that make your wire shelves and wire racks, as well as other wire products. They operate machines, design, supervise operations, control progress, ensure product quality and above all make sure the resulting end product made of metal wire is satisfactory. This is all of course done taking into account the order lead times.

Getting straight to the point – we put work organization first, in order for each manufacturing stage of our shelving unit to be run properly, which always influences the quality of wire shelves. We pay special attention to selecting the materials for the shelf wire, the most common being stainless steel and black steel.

Everything starts from an idea and from individual needs. After choosing the proper material for your wire shelving, we can move on to design – if one is not already available. As a matter of fact, reaching an agreement on the structure of your wire rack or shelving unit is essential, as it allows us to minimize the risk of design mistakes. This approach to manufacturing wire products ensures that everything is perfect down to the smallest detail.

Metal wire comes in large coils to facilitate storage before wire shelving is created from this material. In order to start, we take the design and check the lengths of wire pieces we are going to need for making samples and we cut them accordingly to make the wire racks.

We may call it a kind of gate or a base for each shelf. It gives the shape to the final products. Usually, it is a rectangle or a square. However at this stage, we don’t get a perfect square yet. There is a little gap between the ends and we need to join them.

The wire pieces, bent to the proper shape, are spot welded in one point. This way we make the shelf’s frame. At this stage, we can already see the shape of the future wire shelf.

These are so-called auxiliary wires that may not be included in some models, e.g. some narrow shelves. In a standard, rectangular shape, this wire runs through the middle of the shelf and serves as support for the entire structure of the shelf. There can be several of them, depending on the size and the number of wires to be placed horizontally on them.

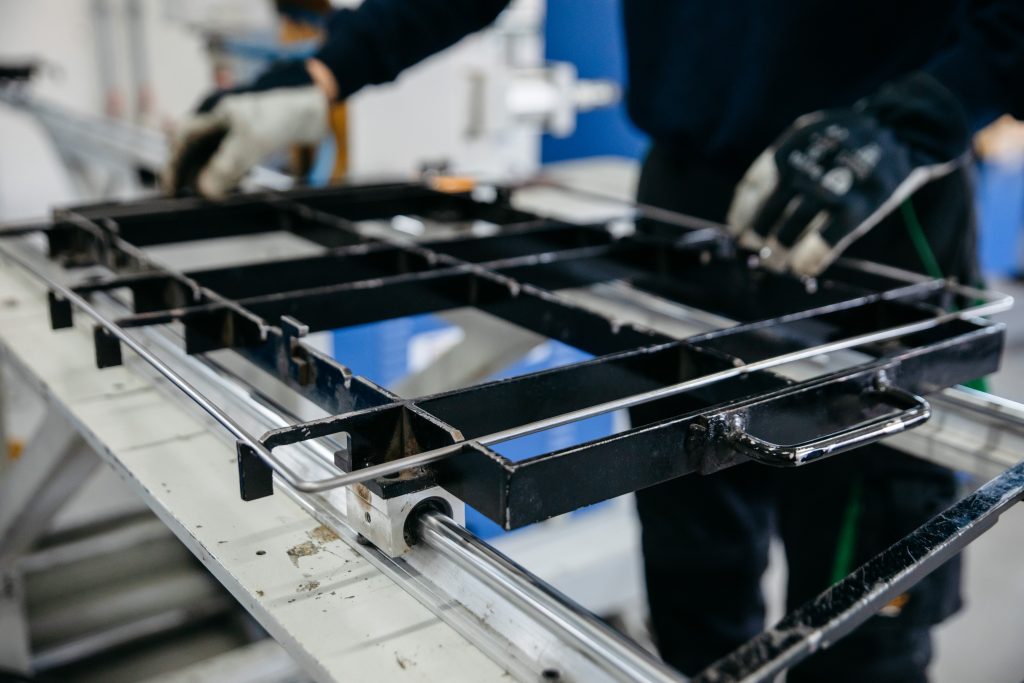

This is the last stage of shelf manufacturing. The thin wires are spot-welded to the previously shaped frame. They will directly support the products put on the rack or into the cooling cabinet. This is the upper part of the shelf.

This stage has probably never been skipped; we always refine details so that the final product is perfect. This may include powder coating the shelves or applying another high quality finish for the shelving units. When shelves are used to serve a particularly demanding purpose, we seek the best supplier of stainless steel wire or other materials for the shelving units. If the design includes some additional elements, e.g. wire side, they are bent and manufactured at this stage. This is done in order for them to become an integral part of the shelf, seamlessly continuing from the shelf to the side.

Storage shelving and commercial wire racks used in the hotel, food and retail industry must meet specific requirements. We have years of experience as a supplier of metal wire racks, which allows us to use materials other than just the regular stainless steel wire. If we are manufacturing a shelf made of black steel, there is one more step to add. We apply a plastified coating on the entire shelf to protect the product and make it more resistant to external factors. At this stage the shelves also get a new color.

The finished product, before being fed into the logistics process and getting to the customer, must be stored properly. Safe storage conditions for wire products account for maintaining quality and prevent damage to the plastified coating.

Manufacturing may seem a relatively simply process. However, to ensure product quality, you need to perform every step thoroughly from the very beginning. This is why SHELMO, as the manufacturer, are committed to keeping the entire order completion process under control and refined through and through for wire applications in various industries.

Wire shelves manufacturer – find us at our website available at www.shelmo.pl. Open the Menu and select the Wire elements tab. Select the browsing option and find categories of wire accessories to match your preferences, depending on the price, final equipment and where the wire rack is to be used in. You may choose your preferred categories according to manufacturing capabilities. As a manufacturer, we are able to complete most projects concerning racks to be used for various storage applications. Price is determined individually, depending on the project.

If you want to know more about wire shelves, click and ask!

Click and fill in the form.

Copyrights © 2021 Shelmo.eu All rights reserved.

Designed by Wizualion.pl Realizacja Woj.Tech Solutions 2021