Share on facebook

Share on email

If you want to know more about the prices of fluidizing.

Click here to complete the form.

Most color components were not created so – they had to undergo a color changing process. The usual word for this process is painting. You can paint almost anything. Different paints and painting accessories are commonly available. Therefore painting is very popular, although it is not always a good solution.

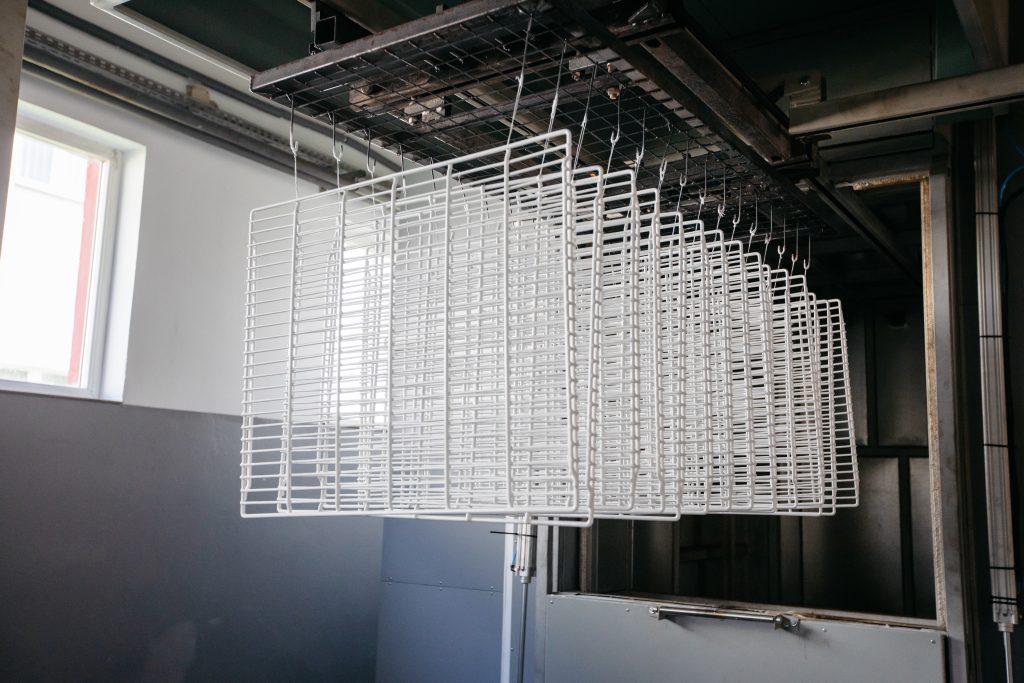

From the chemical point of view, fluidizing is the process of creating a suspension, called fluidized bed, or tiny solid particles in a stream of gas moving from the bottom to the top. This fluidized bed powder coating method can be used for coating various objects; at SHELMO, we fluidize wire shelves.

Once the coated element is treated at a high temperature, the curing stage comes in. This allows to obtain hard layers, ensuring that the surface will be resistant to mechanical factors once fluidized bed powder coating has been applied.

Upon application, powder coatings from the fluidized bed melt to the material, in this case – to metal elements. Depending on the accessories coated. This way, a thick layer of paint remains on the surface, resulting in the impression that the shelf is made of plastic.

Surface preparation is the key stage of the fluidized bed coating process: it involves cleaning and heating the surface in a furnace at a high temperature for several minutes. The powder coating melts with the material perfectly. This method results in a smooth coating.

Works well in the restaurant and hotel industry, where the coating must protect e.g. a glass object when falling down.

We cannot forget the most popular and most commonly used process – powder coating. As part of this method, powder coatings are applied onto a surface, usually a metal one, using an electrostatic field. The main advantage of powder coating is its yield and the ease of the process. Most often, spray powder coating is used. This results in a thin, smooth layer of paint. For this reason, powder coating requires accuracy.

What is the real difference between the methods and how to choose the right one? Contrary to what one might think, powder coating does not provide such a good resistance to corrosion. You often see the coating crack, tarnish or become rough. Take shelves used in restaurants as an example. Powder coating results in a layer that may easily flake off the material, and air bubbles may appear, e.g. if we put down a dish too sharply. In such a case, fluidizing coating will work better, acting as plastic when applied on any element. One might say these are shelves based on a metal superstructure, but with the properties of plastic shelves.

By applying the fluidizing method, we obtain a shiny, smooth and aesthetically pleasing surface, regardless of the surface roughness. This cannot always be achieved using powder coatings. Surface preparation for powder coating is lengthy and the surface must be just perfect. Often, if we make even the slightest mistake – set the wrong temperature, mix the paint insufficiently or clean the surface inadequately, the coating will flake off or be riddled with hollows. Not to mention the fact that the coated material itself must be smooth.

In fluidizing coating technology, the film build is between 0.25 mm and 1 mm, resulting in a very flexible coating and thus providing durability and protection against scratching. Whereas powder coating allows only for applying a thin layer on steel elements. Thinner coating is more prone to weather conditions.

The use of powder coatings at these two stages differs. During powder coating, the paint is sprayed, whereas during fluidization the entire product is immersed in the liquid at once, which results in a consistent film being created. The powder melts with the material perfectly.

There’s no end to the advantages of fluidizing coating, just to mention the possibility to coat any detail using this technique. At SHELMO, we make every effort to ensure that our products and services are always performed at the highest level, including powder coating and fluidizing coating.

If you have any questions about these two processes, we will be more than happy to answer them.

All information is available under the Fluidizing tab.

If you want to know more about the prices of Fluidizing.

Click here to complete the form.

Copyrights © 2021 Shelmo.eu All rights reserved.

Designed by Wizualion.pl Realizacja Woj.Tech Solutions 2021